Date : 12-11-2024

At the “Commendation Conference for Advanced Collectives and Model Workers of Key State-owned Enterprises”, which was sponsored jointly by the State-owned Assets Supervision and Administration Commission of the State Council and the Ministry of Human Resources and Social Security this year, five collectives from China National Building Material Company Limited (CNBM) won the title of "Advanced Collective of Key State-owned Enterprises" and 6 comrades from CNBM won the title of "Model Worker of Key State-owned Enterprises" (click to view). Focusing on the new missions and new positioning of key state-owned enterprises in the new era and on the new journey, the prize winners carried forward the spirit of dedication, kept making innovation, bravely shouldered responsibilities, and worked in a selfless and devoted manner, so that they made important contributions on various fronts such as sci-tech innovation, industrial transformation, and security support, achieved remarkable results, and construed the significance of struggle with their practical efforts and achievements. We have rolled out a special report series titled "Brilliant Craftsmanship · Charms of Advanced Collectives and Model Workers of Key State-owned Enterprises" to share excellent experiences and practices with you, and show the power of role models. Let’s learn from the advanced and keep pace with the role models!

Diligence in Learning and Working, Selfless Dedication

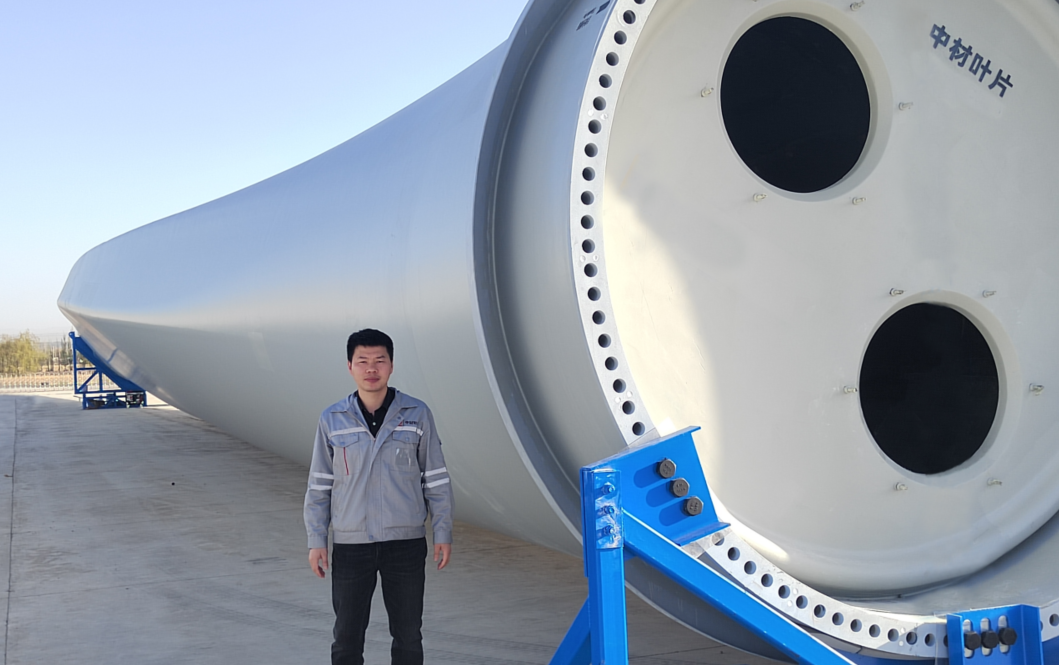

In 2009, Lu Xiaofeng joined Sinoma Wind Power Blade Co., Ltd. (hereinafter referred to as "Sinoma Blade"). Born in 1986, he has been committed to the R&D of large wind power blades for 15 years. Lu has managed or participated in the design and development of 80-odd products, and promoted the increase of turbine power from 1MW to 16MW, with product application scenarios covering multiple extreme environments such as high-altitude onshore mountains and deep/far seas, and cumulative output value exceeding RMB 50 billion. That helps Sinoma Blade's products gain extensive recognition from the market.

Bravely Shouldering Heavy Responsibilities and Overcoming Hard Nuts

The wind power blades become increasingly large, with root load up to hundreds of millions of Newton-meters, implying the damage caused by traditional connection through blade holes has become more sensitive. To overcome such a headache, Lu Xiaofeng led his team to conduct in-depth research on the mechanical properties of the root connection of composite wind power blades, brought in the pre-embedded bar-planting technology from civil engineering. In the end, the team achieved the re-combination of fiber-reinforced composite materials and metals, with pull-out resistance increasing by over 30% relative to the traditional bolted structure with holes. After passing the certification of the international authoritative organization DNV-GL, this technology has been applied to mainstream products in the international market and recognized by international customers. So far, it has brought remarkable economic benefits.

Leading in Innovation and Striving for Excellence

At the end of the 11th Five-Year Plan period, China's wind turbine generator system just advanced onto the MW-level platform, and the import rate of blade raw materials even exceeded 80%. Based on the characteristics of domestically-manufactured materials, Lu Xiaofeng and his team customized the development of blades, and rolled out a positive verification cycle, helping Sinoma Blade successively achieve application of domestically-manufactured materials such as fibers, resins, core materials, and structural adhesives, increasing the localization rate of raw materials from 20% in 2010 to over 95% at present. In 2020, Lu led his team to creatively develop pultrusion-type glass fiber composite plates, with an annual consumption reaching the 100,000-ton level, contributing to China's transformation toward an important power in R&D and manufacturing of glass fiber pultruded plates. In 2021, Sinoma Blade rolled out homegrown carbon fiber pultruded plate beam, which served as a vital component of Offshore 16 MW-122m, the world's longest wind power blade for batch installation. Meanwhile, homegrown carbon fiber pultruded plate also became the first choice of international wind power manufacturers. All these achievements should be highly attributed to painstaking efforts made by Lu Xiaofeng's team.

Concentrating on professional knowledge in the office, tracking the molding process at the workshop, viewing test data on the test site, and checking the operation status in uninhabited wind farms... these scenes constitute Lu Xiaofeng's normal work state. Lu has always maintained the “Diligent and Hardworking” spirit, kept pursuing the craftsmanship spirit of “Striving for Excellence”, and made more efforts and innovations, contributing to the transformation from "Made in China" to "Created in China".

sinomablade@sinomatech.com

Floor 9-10, Building 7, No. 6, Dongsheng Technology Park North Street, Haidian District, Beijing

Follow us